The manufacture of the Massiv-Holz-Mauer®

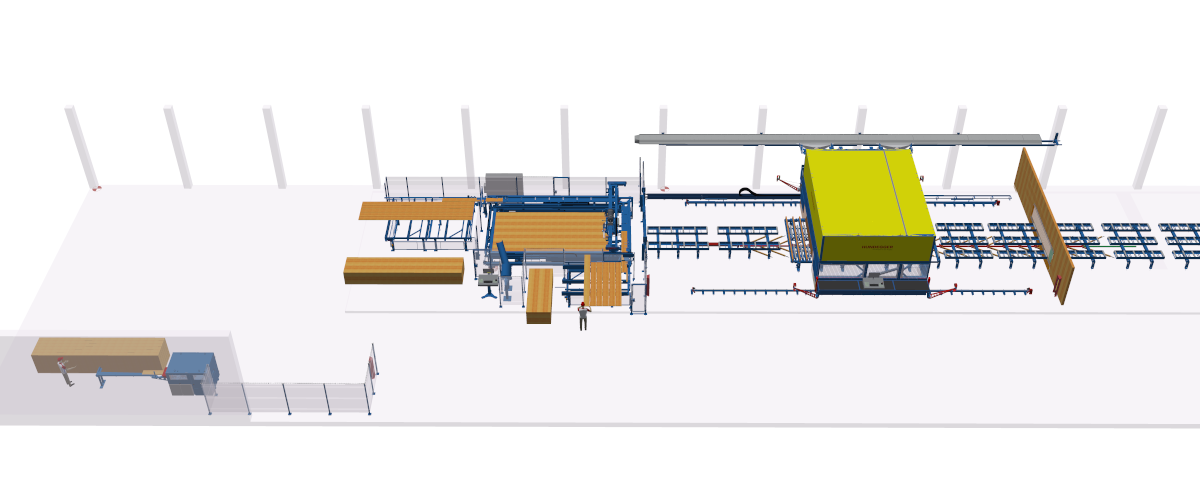

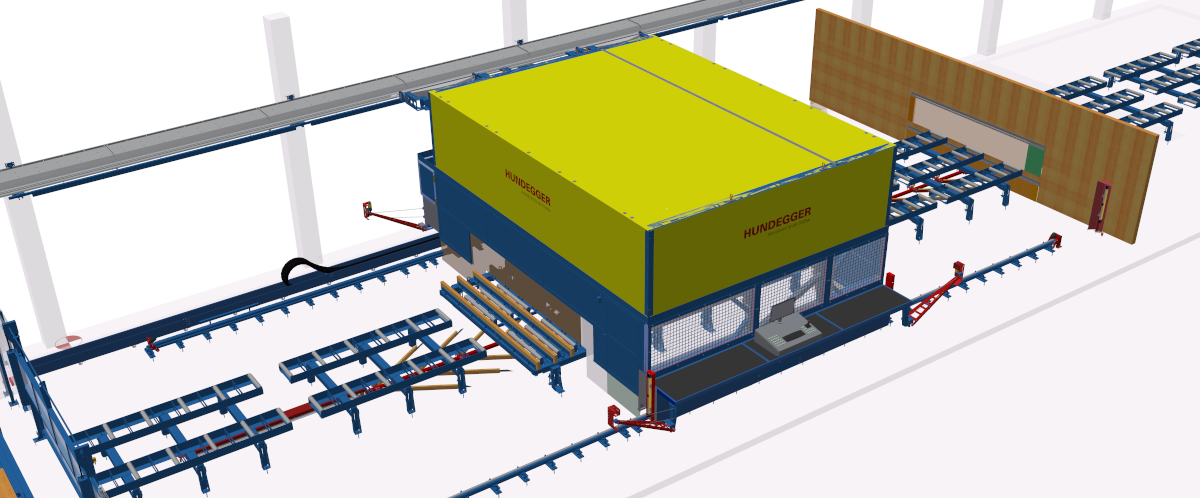

The Massiv-Holz-Mauer® provides medium-sized timber construction companies and the timber-processing industry with an innovative construction product to tap into the solid timber market. It is manufactured regionally on MHM production lines specially engineered by Hans Hundegger AG at around 30 independent manufacturing plants in Europe.

Furthermore, our highly innovative building material is manufactured in an economical and environmentally responsible manner. The basic idea: The Massiv-Holz-Mauer® is manufactured as close as possible to the construction site, in cooperation with companies from the respective region, using timber that is grown and harvested regionally. This concept and all the resulting advantages have enjoyed great and ever-growing popularity from the start until today.

Production in three steps

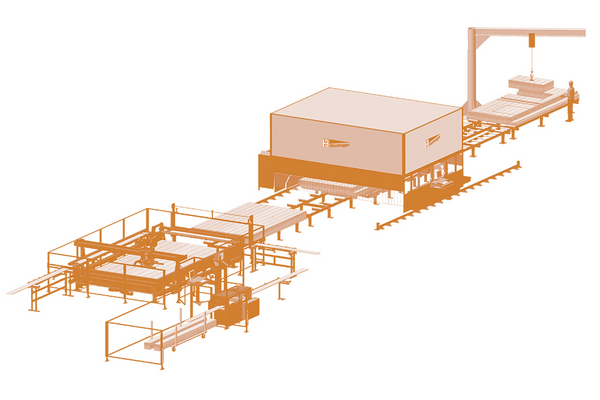

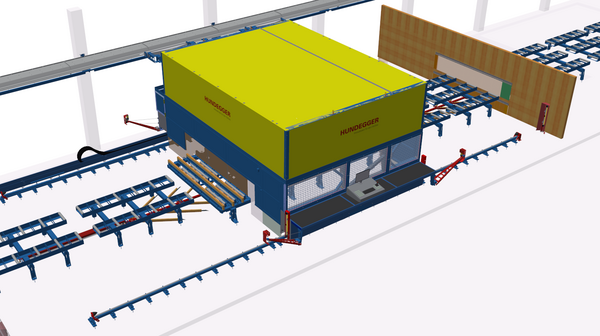

The production process of the MHM production line – from a board to a precision-machined ready-to-fit structural component – involves three steps:

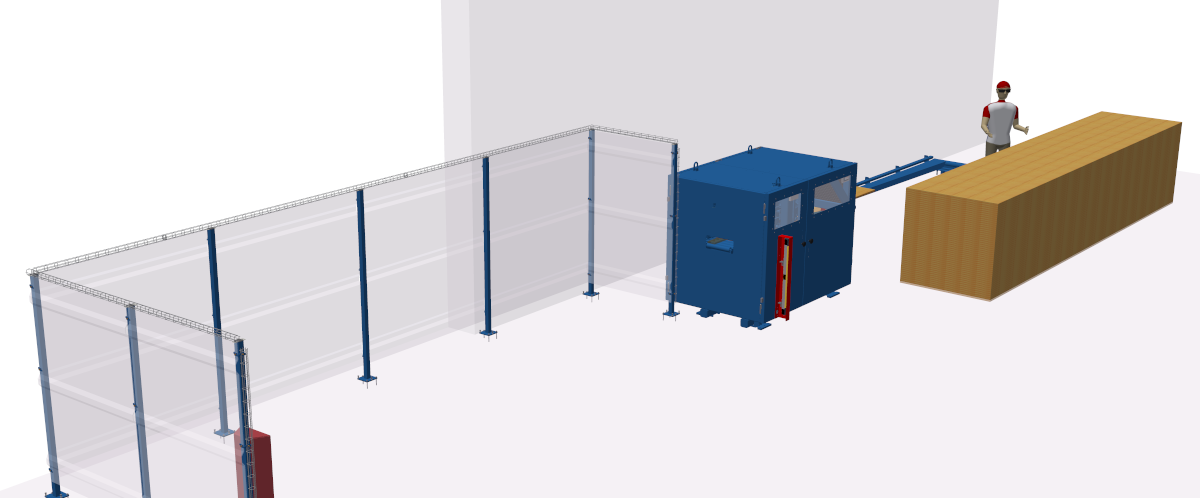

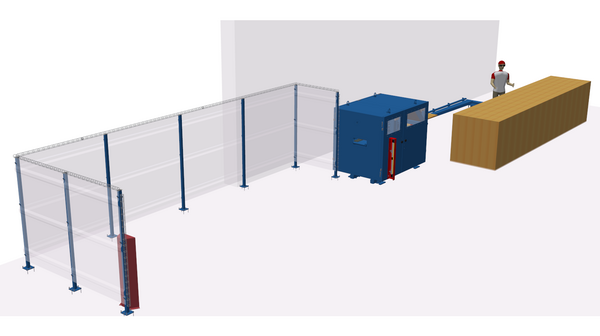

- Groove and rebate milling cutter – grooving and shaping the surface of the boards

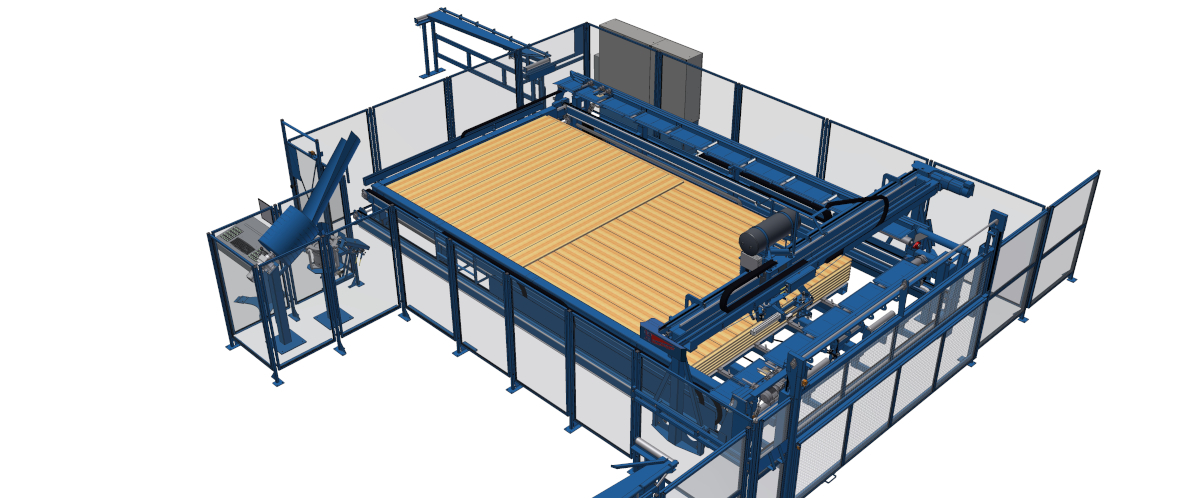

- Wall Master – manufacturing the raw wall elements

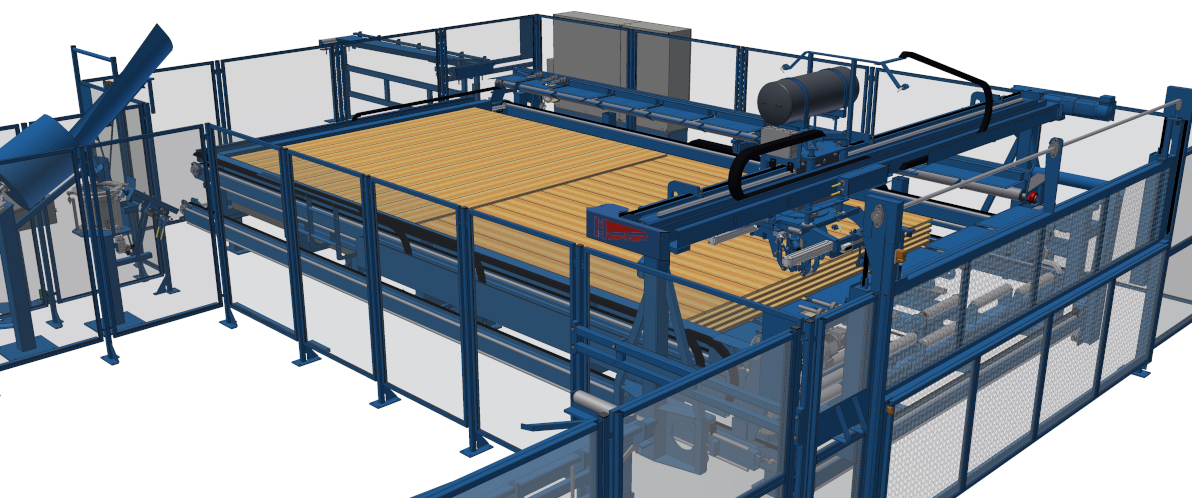

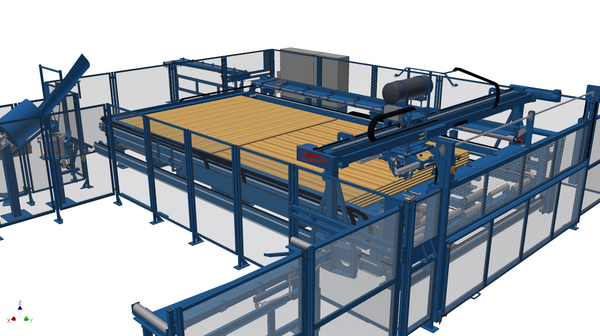

- Panel cutting machine (PCM) – finishing of the wall elements

The grooved boards are subsequently joined layer by layer in a crosswise arrangement in the “Wall Master” to form raw wall panels of the required thickness. In the process, the system can automatically detect varying board widths and positions them precisely so that the profiled aluminium nails are always nailed in at the board intersections and optimal static properties are ensured. To prevent the occurrence of unwanted thermal bridges from inside to outside, the nails only ever penetrate two boards. The loose aluminium nails are fed into the machine individually via a specially developed system. This eliminates the need for magazine-loaded nails, which produce considerable amounts of waste.

In the final process step, the completed raw wall panels are guided by CNC and machined with maximum precision to form ready-to-fit wall elements according to the timber construction and production planning. This is carried out using a panel cutting machine (PCM) with its various units and machining axes, which enable all kinds of machining on the Massiv-Holz-Mauer® element.

First of all, the Massiv-Holz-Mauer® boards are planed or levelled. This creates a smooth wall surface. At the same time, the wall thickness is also precisely mapped.

A 5-axis circular saw is then used to cut the walls to the exact wall length and height. The tolerances are no more than +/- 1 mm. Window and door openings are cut using chain saws and various milling machines and the ducts for sanitary pipes and electrical cables are milled. This is a simple, fast and precise process – there is therefore nothing preventing the implementation of the architectural requirements.

The panel cutting machines are equipped with state-of-the-art software. Thus, the optimal utilisation of the raw wall panels is ensured by nesting. This refers to the process of dividing flat MHM wall panels into smaller elements with as little cutting waste as possible. Exact manufacturing times are also plannable.

The specially developed profiled aluminium nails have a strength similar to wood. This means that the profiled aluminium nails do not cause the cutting tools to wear out.